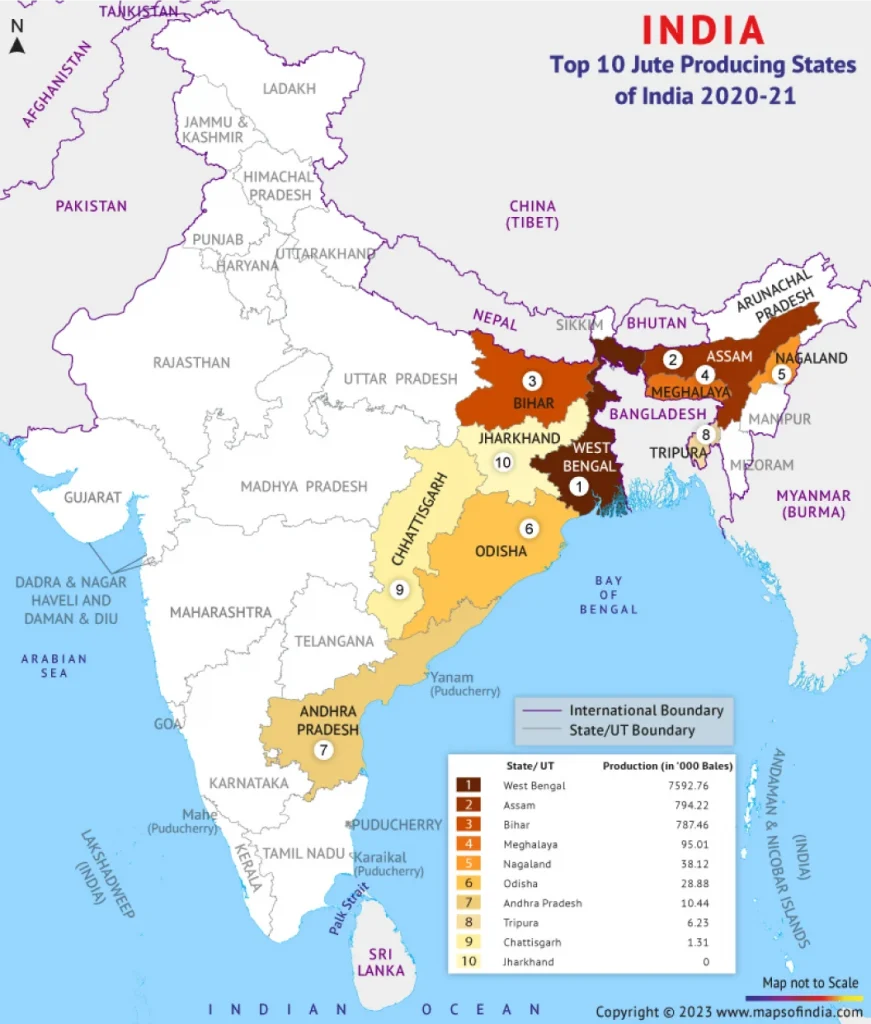

Occupying over 8,00,000 hectares of land for cultivation and employing roughly 3,50,000 workers, the jute industry of West Bengal is one of the oldest and most prominent in India. As a renewable, biodegradable product, jute is both versatile and a vital part of the Indian economy. Currently, India accounts for 75 percent of global jute production with some of the most common products being hessian sacks, food grade cloth, shopping bags, even decorative fabrics.

The Hooghly and its Influence on Jute Production

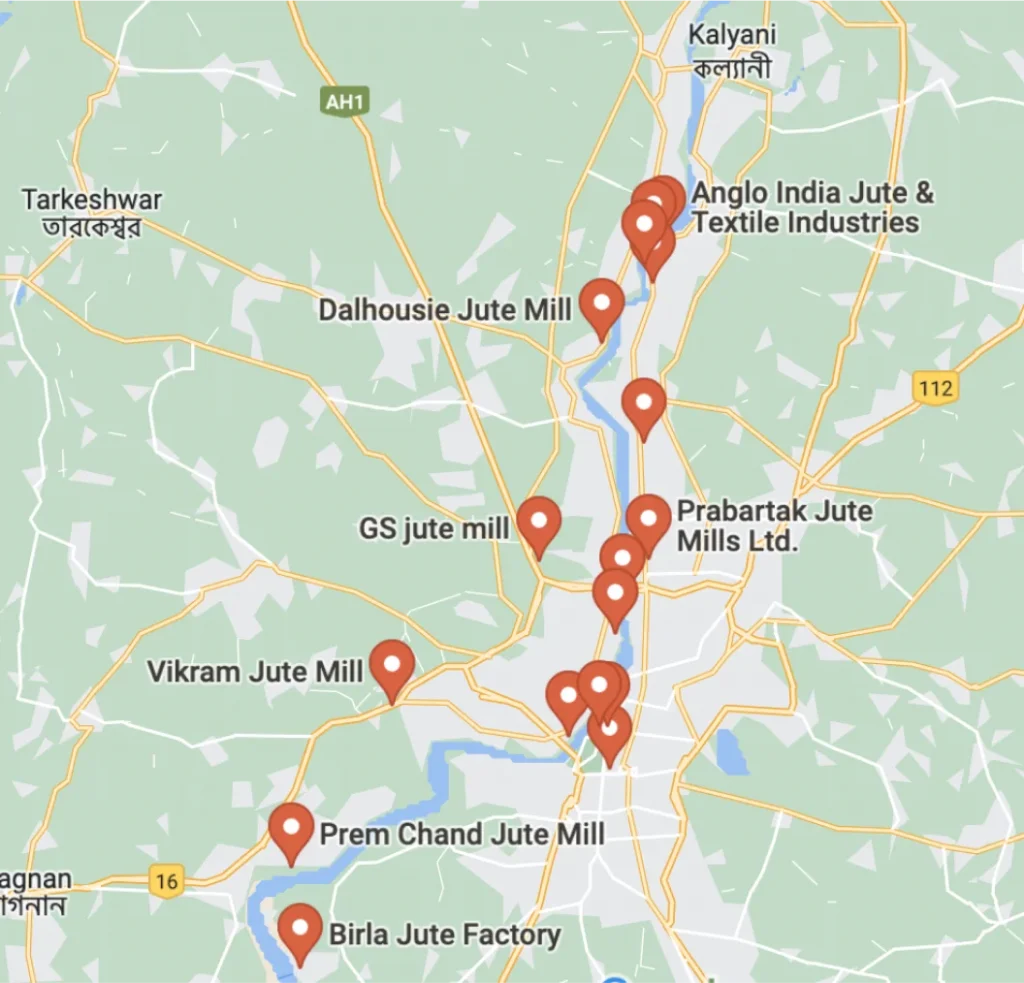

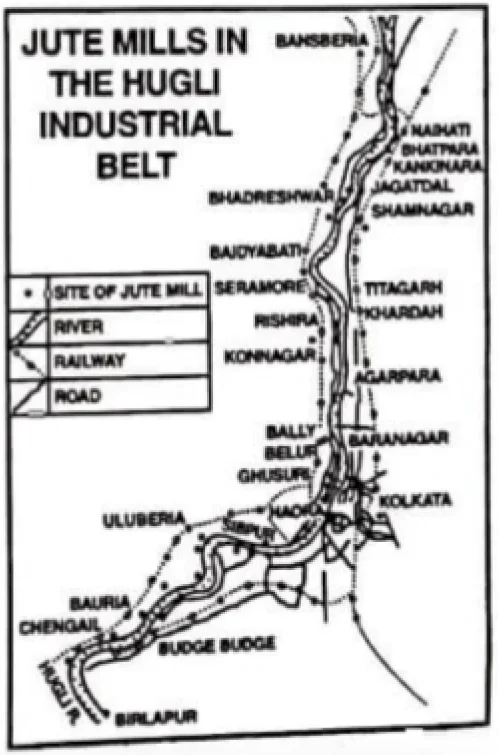

The Hooghly has played a key role in the production of jute in West Bengal owing to the significant amount of water required for its cultivation, and most mills are now situated on its banks. The river basin, an extremely fertile portion of land, is particularly ideal for the cultivation of jute since it is meant to be grown on floodplains (and floods are a recurring event during the monsoon season). Additionally, ports and waterways make for quick and effective transportation of raw material and finished products. Interestingly, the positive economic impact of the jute industry has also played a significant role in the social and cultural development of Kolkata.

The British East India Company was the first jute trader in the 19th century. They used the Hooghly and ports to the Bay of Bengal to export their products, making Kolkata a large hub for the industry. The first jute mill was established in 1856 at Rishra on the banks of the Hooghly by George Acland who shipped jute spinning machinery from Dundee. Four years later, a power-driven weaving factory was set up leading to an exponential rise in demand and exports. By 1939, a total of 68,377 looms were spread across the banks of the Hooghly with a majority near Kolkata. However, the fall of the British empire in India created a temporary blockade of exports from port cities resulting in severe economic challenges to the industry. Much of the material was transported via roadways.

Today, many companies are looking to the Hooghly once again to significantly reduce transportation costs. Now, jute exports from India using the river typically takes 3-4 days. The products are loaded onto barges or ships at the Kolkata port and then transported downriver to the Bay of Bengal.

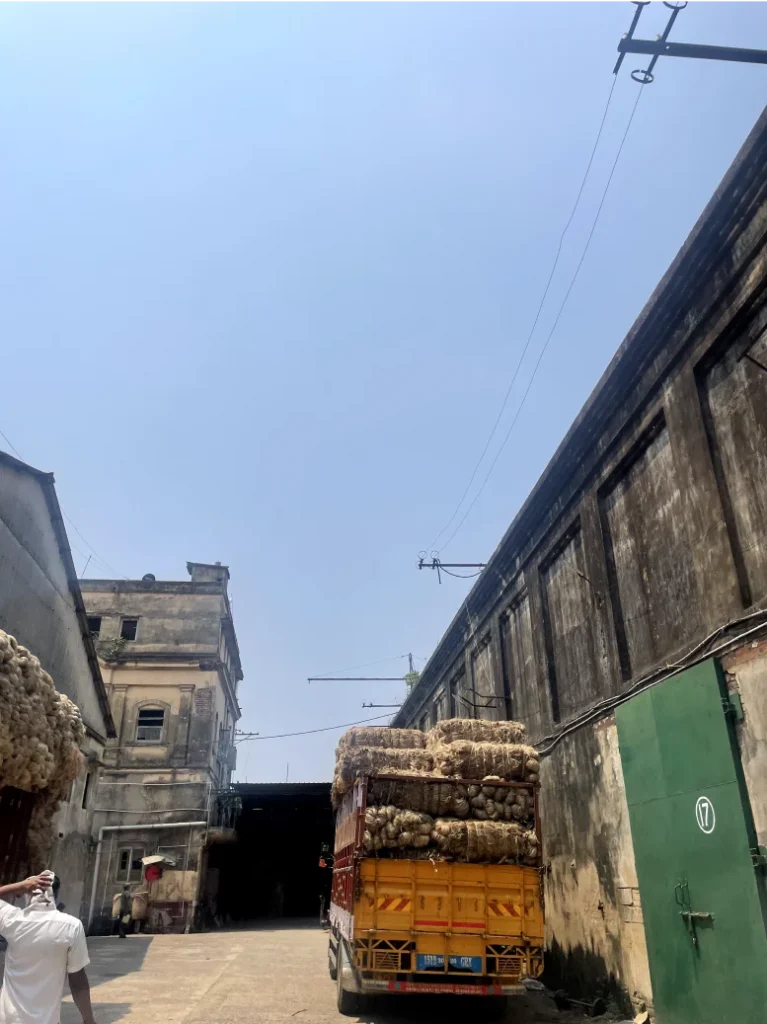

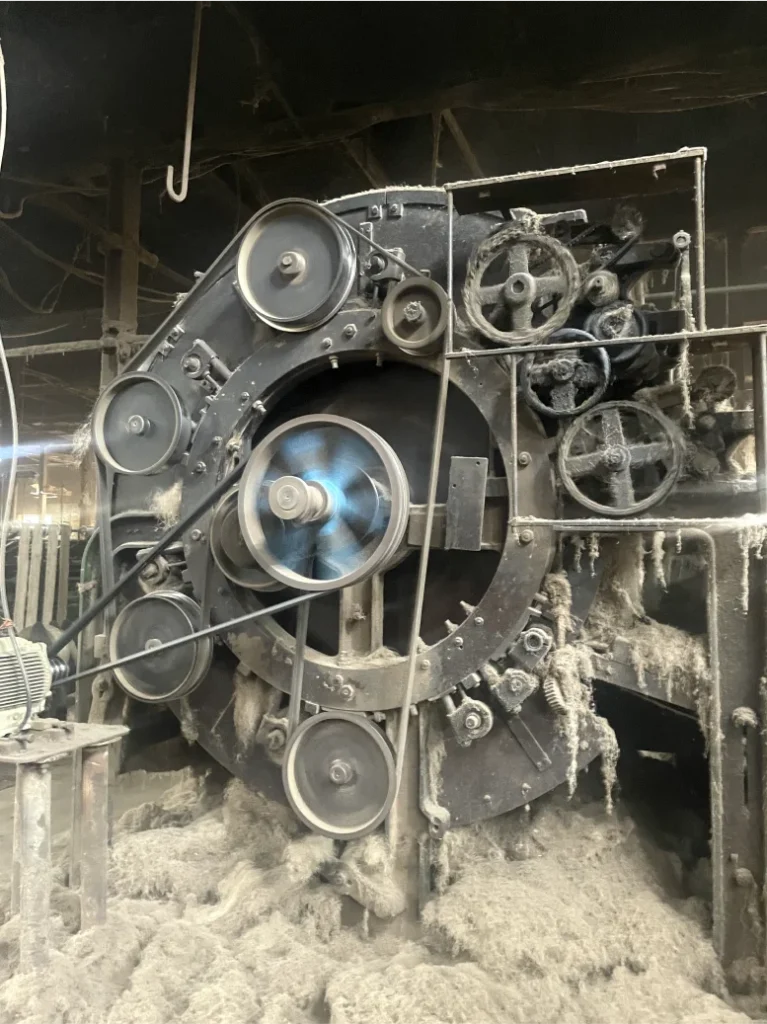

A Visit to the Jute Mill

The Role of Water in Jute Production

Water is paramount to the cultivation of jute since it is a water-intensive crop. From germination to nutrient uptake and fiber extraction, jute relies on water to produce high-quality fiber. It goes without saying that proper water management, including rainwater harvesting, is essential to sustain this crop and maintain its economic and ecological significance. Jute requires about 500 mm of water per year for irrigation, 1000 liters of water per ton of fiber for retting, and up to 200 liters per ton of fiber for processing.

The cultivation of jute relies on rainfall which helps meet the optimal requirements to maintain soil moisture. Changes in average annual rainfall leads to stunted growth thereby affecting the overall quality of the fiber. On the other hand, extreme flooding is also detrimental for jute plants, because of the deprivation of oxygen and reduced nutrient intake. It also goes without saying that climate change and ever-present pollution in the region have severely impacted the quality and production of jute.

Use of water in jute production

The Impact of Water Pollution

Anthropogenic activities such as industrial discharge, untreated sewage, solid waste disposal, and agricultural runoff have polluted the Hooghly considerably. On visiting the Hooghly Jute Mill and learning about jute cultivation, the owner, Ms. Lata Bajoria, emphasized the stark contrast between Bangladeshi jute which retains its golden color, and Bengal Jute which is often dull and gray. She explained that this is due to the differences in purity and quality of water used in jute production. The presence of pollutants in jute fibers also leads to the rejection of products in the international markets. Countries with strict environmental standards on imports often refuse to accept jute products that do not meet their requirements. While the global demand for jute has been declining in recent years, the Indian government has also been promoting the use of synthetic fibers instead of jute. However, as jute is a valuable natural fiber, trade along the Hooghly River will likely continue to be an important part of the Indian economy for many years to come.

Images of Our visit